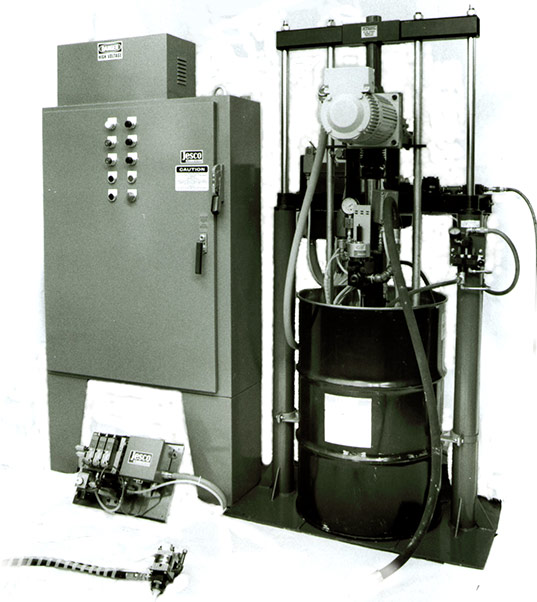

The Jesco Ram Meter Series dispensers are constant flow rate, positive displacement dispensers that can meter low to high viscosity adhesives and sealers directly from the material supply container. They can dispense precisely metered shots or consistent diameter beads at an adjustable and repeatable flow rate.

Because of their Pressure and Temperature Compensated Hydraulic drive package, the Ram Meter Series of dispensers can efficiently and accurately meter materials with better flow control than can be obtained with a reciprocating barrel or pail pump. Since they meter directly from the original supply container, these dispensers do not require supply pumps. This offers the end-user lower overall equipment costs, requires less floor space for the equipment and simplifies / reduces the amount of equipment maintenance required.

Ram Meter Dispensers are available in several different versions, with a multitude of available options.

The N-1890-AE Series Ram Meter pictured above represents a variation in the N-1890 Series of dispensers. The “-AE” suffix stands for Analog Electric dispenser. In this series, the standard Hydraulic Power Unit and Cylinder drive package is replaced with a DC Servo Motor and Inverted Ball-screw Actuator. With closed loop velocity control, this dispenser provides constant flow rates at any given setting. This type of dispenser also responds to an analog signal that is sent from the Robot that is proportional to the flow rate of material required. Analog response with a Hydraulic Drive Ram Meter is also available in the N-1890-AH (Analog Hydraulic) Series dispensers.

All Ram Meter dispensers have various options available to customize their use in a given application. Options such as the “-ROB” option, which provides a Volume and Flow Rate Indicator and Alarm Package as well as Pin Receptacles for interface to a Robot or other Supervisory controller. Timed shot controls for Manual dispense applications. Various Applicator Valves to fit the application. Etc