N-5310 Batch Dispenser

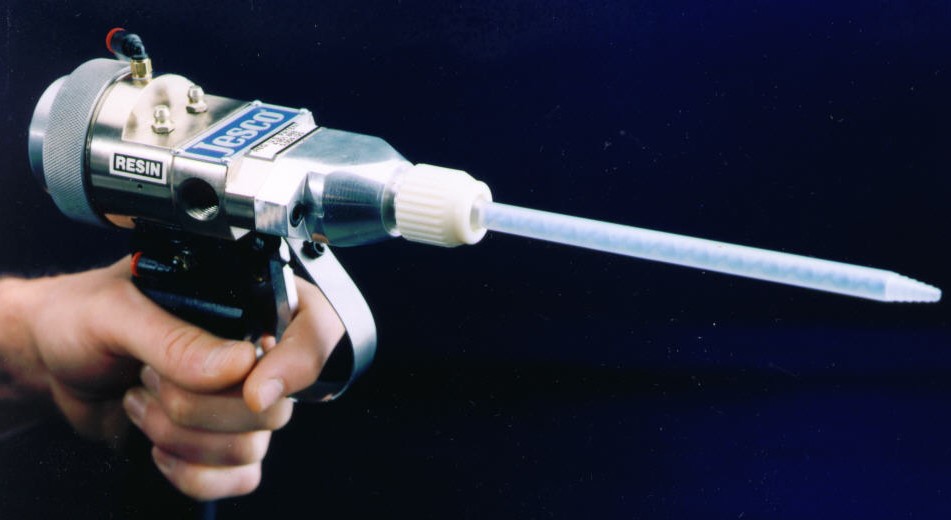

N-1172 Two Component Applicator Mix Gun

The Batch System is a programmable, microprocessor based unit which provides batch control, monitors flow rate and controls the flow of processing liquids. Start/Stop controls can be used in conjunction with pre-warn and final relays to provide valve actuation or pump control. An optional configu- ration offers streamlined preset adjustments, remote Start, Stop & Reset, and weighted averaging.

- Accurately deliver pre-determined shots/batches

- PLC Standard with spare I/O for Cus- tomer Interface

- HMI Display may be toggled between batch, rate, and grand total

- Totally Programmable for Multiple batch Size Requirements

- Viscosities up to 1,000,000 CPS

- Precision Flow meter accurate to

within 2% - Continuous flow capabilities

- Pressure fed inlet up to 3000 psi

- Pressure feed system optional

- Available with optional hand fill gun or Stationary mounted applicator

- 110v Programmable Batch Controller

- Power outlet valve for accurate

shutoff. - The K Factor is used to convert the input pulses or analog input into workable units

- Robot Adaptable

- .2 to 30 liters per minute capability

- Ethernet interface available

- Data Logging Available

JESCO N-1172-S TWO COMPONENT APPLICATOR GUN with motionless mixer for high or low viscosity resin reactive adhesive or sealer materials.

- Design eliminates lead-lag problems. Material inlet positioning maintains volumetric balance of properly proportioned materials.

- Features a flush tip shut-off which facilitates easy cleaning and ratio checking. Shut-off needles are teflon packed.

- Ratio check at the gun makes for a positive indication of ratio at the point of application.

- Quick change connectors makes for fast, easy assembly of mixer to gun.

- Gun and seal design makes for’ a leak-free assembly and reduced seal wear.

- Light in weight, compact in size, well balanced, with convenient pistol grip handle and trigger control.

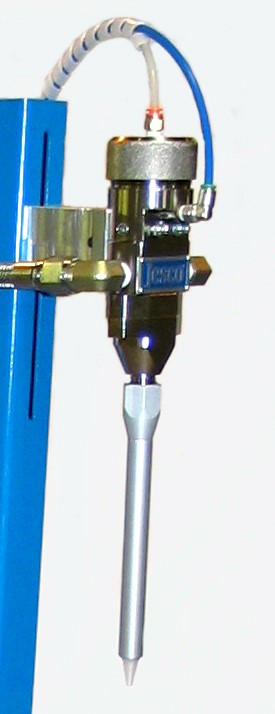

- The pistol grip handle is removed and an air cylinder actuator is added to make a compact, streamlined mixer-applicator that is designed for machine mounting and automated operations.

- Immediate response when material is called for and quick cleanout when solvent flush is activated.

AIR POWERED FLOW APPLICATORS for manual applications.

- Hand-held, light weight, trigger controlled.

- Applicable to high or low viscosity materials for high or low volume applications.

- Designed to process single component or plural component mixed materials.

*For Single component applications, order the N-17 series. For plural components, special seals and pistons will be used.